Introduction

The demand for fast, predictable connectivity has exploded. Cloud applications, UHD video, VoIP, remote working, smart buildings, and IoT all depend on a network that can shift vast volumes of data without hiccups. Traditional copper wire has served us for decades, but it struggles with bandwidth, distance, and electromagnetic interference. Fibre optics solves those limits by sending data as light rather than electricity.

TL;DR (Quick answer)

- Fibre optics transmit light signals through ultra-thin strands of optically pure glass, each about the thickness of a human hair.

- Using total internal reflection, the light beams stay contained within the fibre’s core diameter.

- Data travels close to the speed of light with very little signal loss.

- Unlike copper cables, fibre is immune to electromagnetic interference.

- Fibre is highly secure and capable of carrying computer data.

- Works across both short distances (in buildings, data centres) and long distances (between cities and continents).

This article explains how fibre optics work in clear terms, whilst diving deeper into:

- The physics – refraction, total internal reflection, critical angle

- The glass structure of cables – core, cladding layer, coatings, jackets

- How single mode fibers differ from multi mode fibers

- How light is generated and detected

- Where losses arise in fibre systems

- How fibres are installed and tested

- How they connect into your home or business

- Where fibre wins over alternatives

- The practical downsides to consider

- How to choose the right option for your building infrastructure

Fibre optics in a nutshell

Fibre optics is a method of transmitting data as light pulses through thin strands of optically pure glass (or sometimes plastic fibers). Each strand—an optical fiber—is about as thin as a human hair yet can carry data over long distances with remarkably low signal loss. Pack many fibres together in a sheath and you have fiber optic cables (often called optical fiber cables or simply optical cables) that form the backbone of modern computer networks, the internet core, telephone calls, and even cable TV distribution.

Where copper uses electrons, fibre uses photons. Because light travels through glass with minimal attenuation and is immune to electromagnetic interference, fibre can deliver huge bandwidth over tens to hundreds of kilometres without constant amplification. This is why fiber optic communication powers everything from transoceanic links to in-building risers.

The physics: refraction, critical angle, and total internal reflection

To understand why fibre optic works, let’s start with refraction.

When light passes from one material to another – say, from silica glass to air – its speed changes, and the path bends according to Snell’s Law.

In an optical fibre, we exploit this with a very thin core made of doped silica (for controlled refractive index), surrounded by a cladding layer with a lower refractive index. That difference is deliberate: when light rays travelling in the higher-index core hit the core–cladding boundary at a shallow angle, they meet or exceed the critical angle and reflect back inwards instead of escaping. This phenomenon is total internal reflection.

Think of it like a glass corridor. The light beam bounces off the corridor walls countless times, but it keeps moving forward. Because the reflections are loss-light and repeatable within tolerances, the light signals inside the fibre transmit signals with very low signal loss even as the cable bends within its specified radius. This is the essential trick that lets signals travel straight down a fibre across astonishing distances.

Inside a fibre: the glass structure and cable build

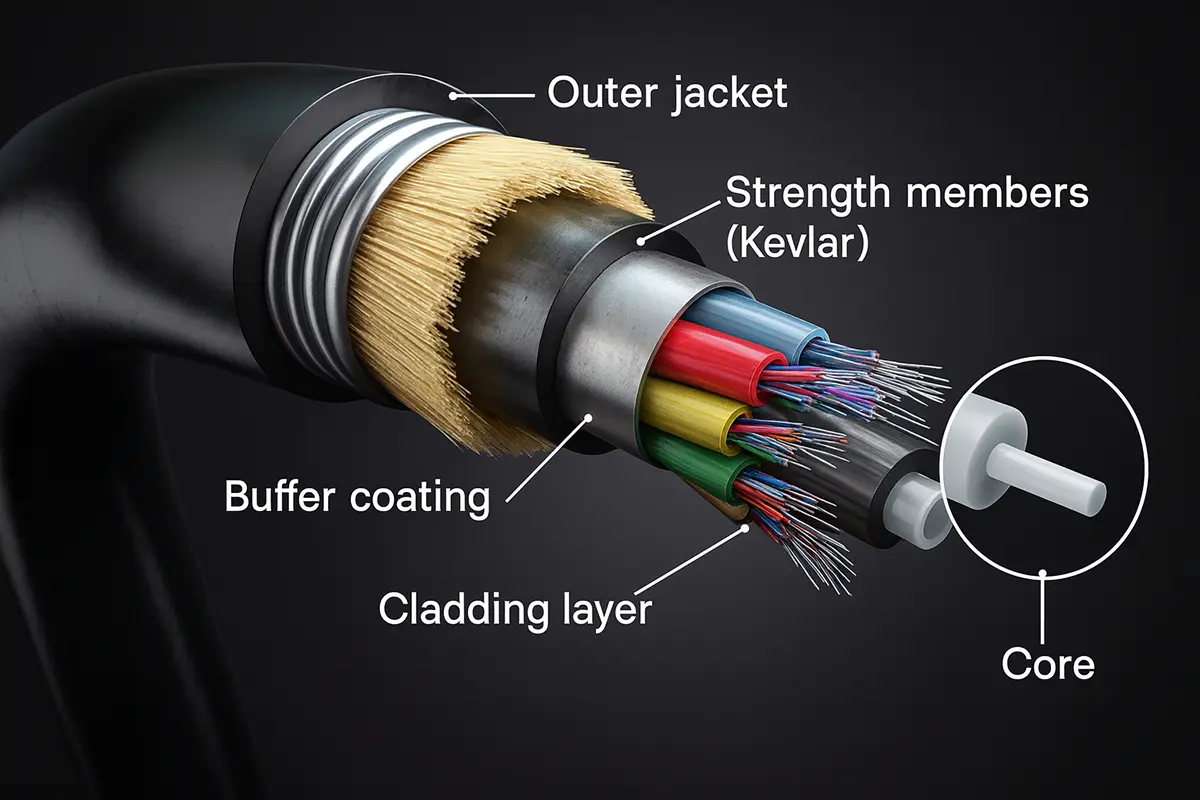

Each fibre is a precision component:

- Core – The central pathway where the light travels. The core diameter (measured in microns) determines if the fibre is single mode or multimode.

- Cladding – Glass around the core, with a lower refractive index to keep the light trapped by total internal reflection.

- Primary coating / buffer – A protective polymer coating to protect the glass from micro-bends and handling damage from human body oils or moisture.

- Strength members & outer jacket – Aramid yarns, ripcords, water-blocking tapes, armour and sheath materials make up the full fibre cable. Bundled together you get robust optical fibre cables for ducts, trays, outdoor routes or direct burial.

Single mode vs multimode: which mode fibres and when?

“Mode” describes the electromagnetic propagation paths supported within the core.

Single mode (OS1/OS2)

- Core diameter ~8–10 μm.

- Carries only one mode of light, so there’s no modal dispersion.

- Optimised for wavelengths 1310 nm and 1550 nm; attenuation is extremely low.

- A typical single mode fiber supports long distances (tens of kilometres) without repeaters and underpins wide-area and campus backbones.

- A single mode cable with modern optics can handle staggering bandwidth using DWDM.

Because only one path exists, different paths arriving at different times isn’t an issue. This delivers very high performance and reach.

Multimode (OM3/OM4/OM5)

- Core diameter 50 or 62.5 μm.

- Supports multiple different modes, i.e., light follows different paths through the core.

- Uses VCSELs/LEDs as the light source; cost-effective optics for short distances (e.g., 100–150 m at very high rates).

- Multi mode cables are standard in data halls and office floors where runs are short and bandwidth is still huge.

Rule of thumb: if you need campus or metro links, go single mode. For in-room/in-floor patching across relatively short distances, multi mode is cost-effective. RJ Electrical Contractors can design mixed environments that sensibly balance optics cost against reach and capacity.

From electrons to photons and back: how equipment talks over fibre

Networks are still electronic at their edges—servers, switches, and routers process computer data electrically. Transceivers bridge the gap:

- Electrical signals (from switch/router/ONT) feed the transceiver.

- The transceiver converts data into light pulses using a light source (laser/LED). It may encode the stream (NRZ/PAM4) and set the output power for the fibre type.

- The distant receiver uses a photodiode to convert arriving light into electrical signals again.

In short, fibre transmits light, not current. That’s why it’s immune to ground loops and electromagnetic interference, and why it’s extremely secure against unnoticed tapping compared with copper wire.

Loss and dispersion: what weakens the signal?

Even with superb glass, nothing is perfect. Engineers manage two main impairments:

- Attenuation (signal loss) – Light gradually weakens as it travels. Causes include absorption in glass, Rayleigh scattering, splices/connectors, and macro-bends. Good installation practice (clean ferrules, correct bend radius, high-quality fusion splices) keeps this tiny.

- Dispersion – The pulse spreads out in time.

- Modal dispersion (multimode): different modes take different paths and arrive at slightly different times.

- Chromatic dispersion (single mode): different wavelengths within the pulse propagate at slightly different speeds.

- Polarisation-mode dispersion (PMD): ultra-high-speed concern in long single-mode links.

Why it matters: as pulses broaden and weaken, receivers might misread symbols. Designers choose cable types, wavelengths, and optics that keep dispersion within budget so signals travel straight through the link at target rates.

Testing & verification. OTDR (Optical Time-Domain Reflectometer) launches a pulse and measures reflections to map splice loss, breaks, and connector quality. Light-source & power-meter tests, plus end-face inspection and cleaning, complete a proper commissioning suite.

How fibre is connected to your premises (home or business)

For FTTP/FTTH or enterprise links, the high-level steps are similar:

- Outside plant brings fiber optic lines from a street cabinet or exchange towards your building via ducts, trays, poles, or micro-trench routes.

- A single fiber (often in a small drop cable) enters the premises.

- It terminates in a wall outlet or panel and then into an ONT (Optical Network Terminal).

- The ONT converts the light signals to electrical signals your router or switch can use.

In multi-tenant or campus sites, a main equipment room receives incoming optical cables which then fan out through risers to telecoms rooms on each floor. RJ Electrical Contractors design and install this structured plant so backbones and spurs are tidy, labelled, and scalable.

On commercial projects, we integrate fibre with copper where it makes sense (PoE phones, access points, endpoints). See Network Cabling Services for the full design–install–test package.

Choosing between single mode and multimode for your building

Key considerations:

- Distance & topology. Campus or building-to-building = single mode. In-floor links under ~150 m at high rates = multimode.

- Bandwidth roadmap. If you anticipate many 100G/400G uplifts, single mode gives you headroom.

- Cost balance. Multimode optics can be cheaper at the switch, but cable/future limits may weigh against it.

- Compatibility. Ensure transceiver form-factors match your switches (SFP+, QSFP-DD, etc.) and fibre counts line up with trunking.

RJ Electrical Contractors can specify exact core diameter, connector types, and trunk/backbone models that match your kit list and building constraints.

Fibre vs copper vs Wi-Fi

Key considerations:

- Fibre vs copper cables

- Carry signals farther with less signal loss.

- Immune to electromagnetic interference (motors, lifts, radio, fluorescent ballasts).

- Higher secure carriage—difficult to tap invisibly; overall extremely secure.

- Smaller, lighter cables with far greater aggregate bandwidth.

- Fibre vs Wi-Fi

- Fibre is the physical transmission medium.

- Wi-Fi distributes that bandwidth wirelessly indoors.

- For deterministic performance, wired fibre links beat radio. Wi-Fi is the convenience layer on top.

Copper still shines for short distances to power devices (PoE) and low-speed legacy kit. But as a backbone, fibre wins on practically every metric.

| Medium | Typical Bandwidth | Practical Speed & Reach | Interference / EMI | Security | Latency / Jitter | Install & Maintenance | Best For |

|---|---|---|---|---|---|---|---|

| Fibre optics | Very high (DWDM-capable) | 10G–400G+ over long distances (km+) | Immune to electromagnetic interference | Extremely secure; hard to tap undetected | Very low; stable over distance | Requires splicing, cleaning & precise handling | Backbones, campus links, data centres, future-proof networks |

| Copper cables (Ethernet) | Moderate–high (depends on Cat rating) | 1–10G to ≈100 m per channel | Susceptible; shielding & separation needed | Good; easier to tap than fibre | Low on short runs | Simple termination; supports PoE | Workstation drops, PoE devices, short horizontal runs |

| Wi-Fi (wireless) | Shared; varies by standard & environment | High peak in room; drops with range/obstructions | Subject to congestion & radio noise | Strong with proper configs; over-the-air exposure | Higher/variable vs wired | Fast to deploy; AP placement & tuning required | Mobility, guest access, devices without cabling |

Figures are indicative; actual performance depends on cable grade, optics, environment and configuration.

Cable types, connectors, and practicalities

Cable constructions: indoor tight-buffered, loose-tube, gel-filled, armoured, dielectric; outdoor UV-resistant sheaths; micro-ductable mini-cables for high-count routes. Each option controls crush resistance, moisture protection, rodent defence, and bend performance.

Connectors: LC (small form factor), SC (older, larger), ST (bayonet legacy), and MPO/MTP (multi-fibre for high-density trunks). Polarity and fibre mapping matter—especially with MPO, which can be Type A/B/C and flipped.

Cleanliness: Dust is the enemy. Always inspect and clean with proper tools; a bit of residue on an end-face can look like a boulder to light at 1,310 nm.

Bend radius & pulling tension: Respect manufacturer limits. Micro-bends and sharp turns add signal loss; over-pulling can fracture the thin core and thin strands.

Splicing: Fusion splicing aligns fibre ends at micron precision and uses an arc to fuse them, achieving minimal insertion loss. Mechanical splices exist but are best reserved for temporary fixes or very short distances.

How much faster is fibre—really? (speed of light, practically)

Light travels through glass in fibre optic cables at about two-thirds the speed it does in empty space (vacuum) because of the properties of silica glass. Even though it’s a bit slower than in a vacuum, fibre optic cables still send data much faster and with much less delay than traditional copper wires.

This means for activities like cloud computing, video calls, or large data transfers, fibre optics provide quicker and smoother performance, making your online experience better and more reliable.

How light is encoded: “blinking” faster than you can blink

Although we speak of light pulses, modern systems often modulate the light wave more cleverly than simple on/off. Advanced line coding and multi-level modulation pack more bits per symbol while keeping within dispersion and noise budgets.

The result: a single fiber can move colossal amounts of computer data simultaneously—think multiple colours (wavelengths) each carrying an independent channel (DWDM/CWDM).

Safety and handling

- Eye safety: Invisible IR can be dangerous—never look into live fibres.

- Fibre shards: Tiny glass splinters are hazardous; dispose of off-cuts correctly.

- Labelling & documentation: Good records make future expansions and faults straightforward.

- Separation: Keep fibres away from sources of heat or crushing; route sensibly in trays and trunking.

Beyond broadband: other uses of fibre

Fibre isn’t only for the internet:

- Medical: Endoscopy uses plastic fibers and glass fibers to relay light in the human body.

- Industrial: Noise-immune links for machinery and monitoring—excellent for carrying computer data where EMI is rife.

- Defence: In military equipment, fibre’s EMI immunity and difficulty to tap are advantages.

- Sensing: Fibre Bragg gratings detect strain, temperature, and vibration across long distances with tiny mass.

- Broadcast: Remote camera links and contribution networks.

- Legacy: Cable TV distribution still leans heavily on optical trunks.

Timeline: Evolution of Fibre Optics

-

Early physics experiments explored refraction and guiding light, laying the groundwork for modern optical fibre technology.

-

Bundles of glass fibres were used to transmit images inside the human body, leading to clinical endoscopes.

-

Corning demonstrated optically pure glass with attenuation under 20 dB/km, proving fibre could surpass copper cables for telecoms.

-

Wide roll-outs replaced copper wire in core networks, enabling reliable long-distance fibre optic links.

-

Transoceanic cables carried global internet traffic, cementing fibre as the primary transmission medium.

-

Fibre optic lines now reach homes and businesses directly, powering cloud, streaming and high-speed computer networks.

What are the downsides of fibre-optic internet and infrastructure?

No technology is perfect. The main drawbacks:

- Fragility: The glass thin core is inherently brittle without proper protection.

- Specialist skills: Installation, splicing, testing, and fault-finding require trained engineers and dedicated tools.

- Initial cost: Plant and optics can be pricier than copper at small scales, though the gap narrows every year.

- Availability: Some areas still await comprehensive roll-out of fiber optic lines.

Yet, for most organisations, fibre’s performance, reliability, and longevity outweigh these concerns decisively.

Planning a fibre build with RJ Electrical Contractors

The deployment process follows clear, simple steps:

- Survey & design – Route planning, link budgets (attenuation + dispersion), strand counts, optical cables type (armour/duct grade), and tray allocations.

- Product selection – Single mode vs multi mode, proper core diameter, connector standards, and transceiver compatibility at each node.

- Installation – Correct pulling, bend radius, segregation from power, and safe routing.

- Splicing & termination – Fusion splices, pigtails, patch panels; MPO trunks for high density where appropriate.

- Testing & certification – OTDR traces, loss testing, end-face inspection.

- Handover – As-builts, labelling, and documentation for future maintenance.

This joined-up approach ensures your fibre backbone is reliable, scalable, and neatly integrated with copper edge runs for endpoints and power.

Learn more about our end-to-end structured cabling approach on Network Cabling Services.

FAQs

How does fibre optics work?

Fibre optics works by sending light pulses through a very thin core inside the fibre. The core has a higher refractive index than the surrounding cladding layer, so when light rays hit the boundary at a steep enough angle (above the critical angle), they bounce back inside instead of escaping. This is called total internal reflection.

At one end, devices convert electrical signals into light pulses to send down the fibre, and at the other end, receivers turn the light back into electrical signals. Because very little light is lost along the way, fibres can carry data over long distances without needing frequent signal boosting.

What is the downside of fibre-optic internet?

Mainly installation complexity and the need for specialist tools and training. Fibres are also more delicate than copper and can be damaged if bend radii or pulling tensions are ignored. Availability can be limited in some regions.

However, once installed, fibre is more reliable, immune to electromagnetic interference, and extremely secure compared with copper.

How do they connect fibre optic to your house?

Providers run optical cables through ducts or along poles to a nearby cabinet, then a drop cable brings a single fibre into your premises.

It terminates at an ONT, which converts the light signals into electrical signals for your router. Inside larger buildings, fibres are distributed via risers and patch panels to reach comms rooms serving each floor.

Is fibre optic better than Wi-Fi?

They serve different roles. Fibre is the fixed transmission medium delivering high-capacity backbones; Wi-Fi is a local radio network that shares that capacity wirelessly.

For reliability, determinism, and throughput, wired fibre links outperform Wi-Fi. Wireless adds mobility, not raw capacity.

Is fibre faster than copper for short runs?

Even over short distances, fibre typically delivers higher bandwidth and lower error rates, and it shrugs off EMI that can plague copper. Copper can still be sensible for endpoint runs or where PoE power is required, but backbones and uplinks are best on fibre.

How thin is the fibre core compared with a human hair?

A human hair is roughly 70–100 μm in diameter. Multimode core diameter is usually 50 or 62.5 μm; single mode is about 8–10 μm. Including cladding and coatings, a single strand is still remarkably small.

What produces the light in a fibre system?

Transceivers use LEDs or lasers as the light source. Multimode links often use VCSELs; single mode uses laser diodes optimised for 1,310 or 1,550 nm bands.

Can a single fiber carry multiple channels?

Yes. Wavelength-division multiplexing splits the spectrum into many “colours,” so one fiber can carry signals from many logical channels at once. That’s how undersea cables and metro rings move such vast traffic.

Does fibre carry electricity?

No. Fibre doesn’t conduct; it transmit light only. That’s why it’s immune to surges and ground potential issues that can affect metallic media.

Where is multimode best, and where is single mode best?

Multi mode excels at relatively short distances in buildings and data centres with cost-effective optics. Single mode is the choice for long distances, high speeds, and future-proofing.

Is fibre really secure?

Yes. It’s extremely secure compared with copper. Non-intrusive taps are difficult to install without detection because they disturb the optical power balance and often introduce reflections visible in test traces.

Summary: why fibre is the sensible default for modern networks

- Capacity: Far more headroom than copper.

- Reach: Tens of kilometres between active devices for single mode.

- Resilience: Immune to EMI and environmental issues that derail copper cables.

- Security: Much harder to tap undetected.

- Scalability: Trunks, MPO backbones, DWDM—build once, scale later.

- Versatility: From computer networks to sensing, broadcast, and military equipment communications.

For most organisations, the question isn’t “fibre or copper?” It’s “how much fibre, and where?”

Check Your Fibre Performance

Distance Loss Calculator

Enter the run length and choose fibre/wavelength to estimate optical attenuation.

Figures are indicative; actual loss depends on cable grade, bend radius, cleanliness, and installation quality.

Bandwidth Estimator

Choose fibre and distance to see typical speeds supported for that link length.

Rules of thumb. Exact capabilities depend on optic type (e.g., SR/LR/ER/ZR, VCSEL/laser), dispersion, and optical budget.